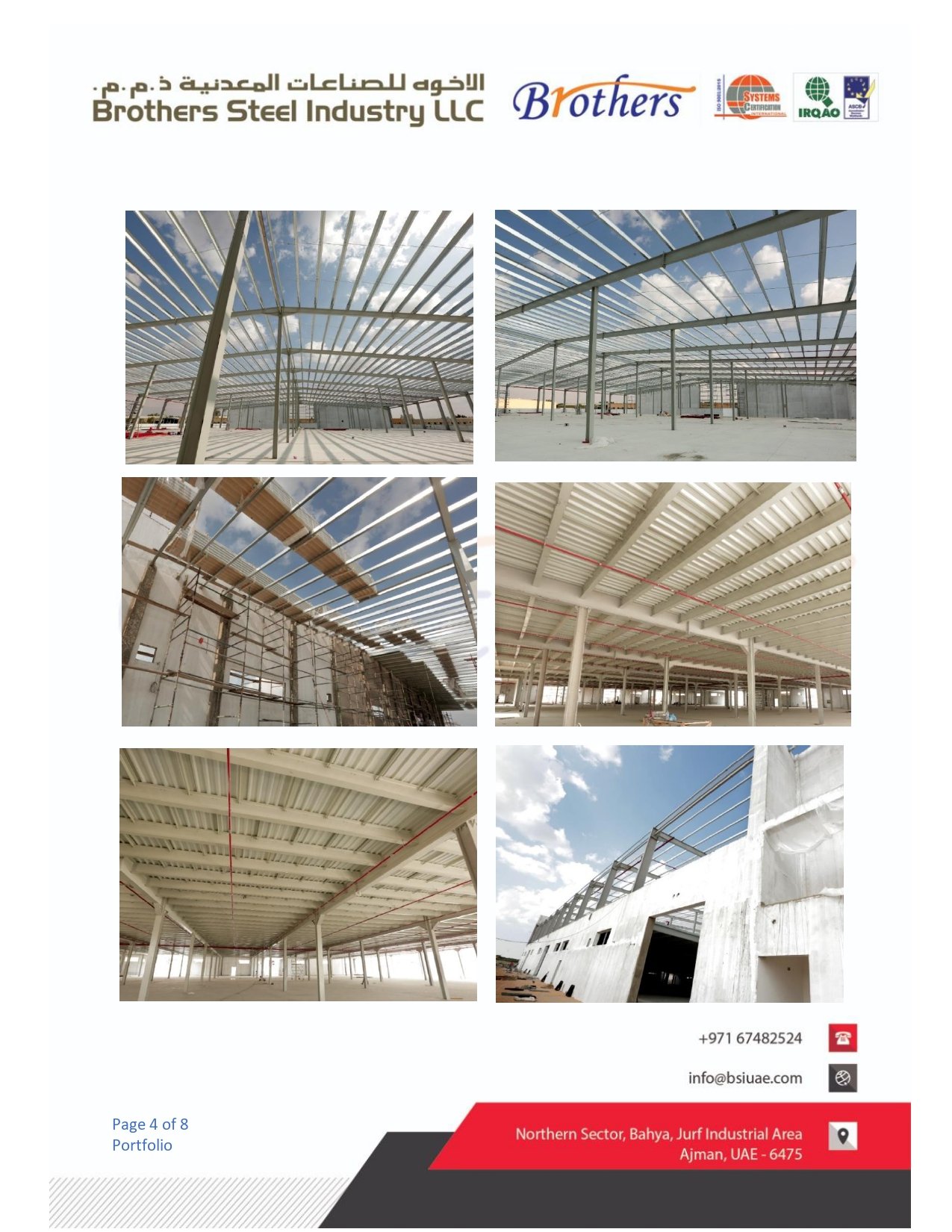

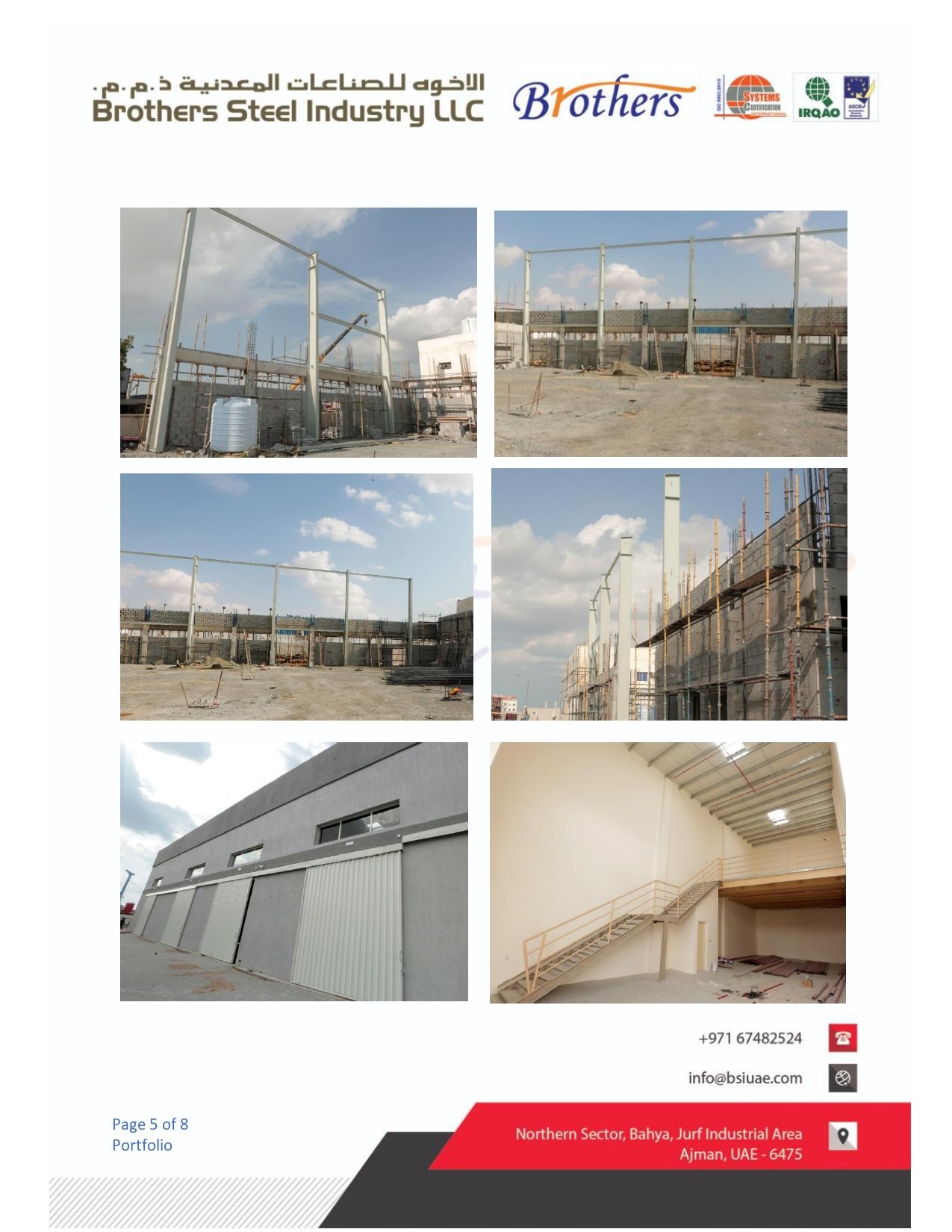

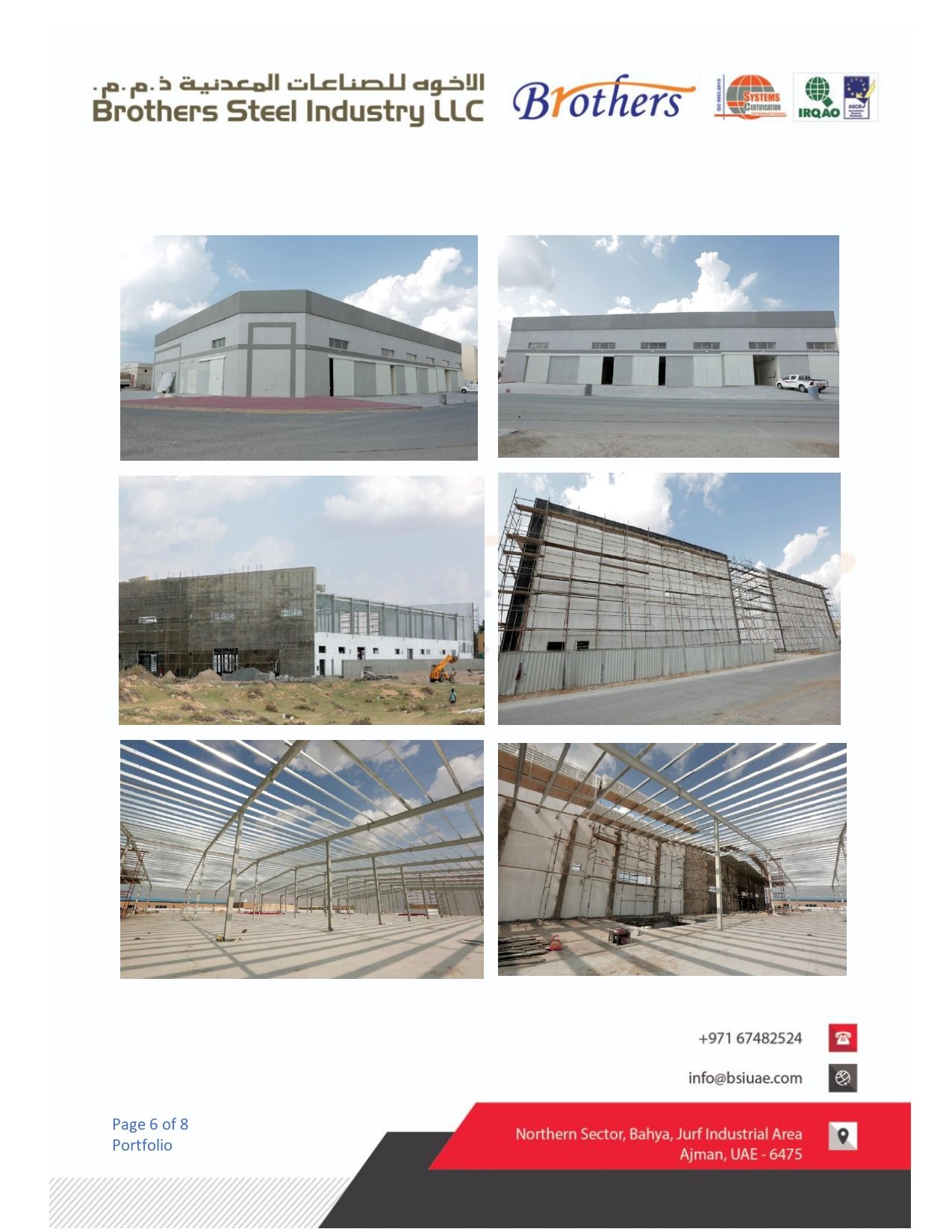

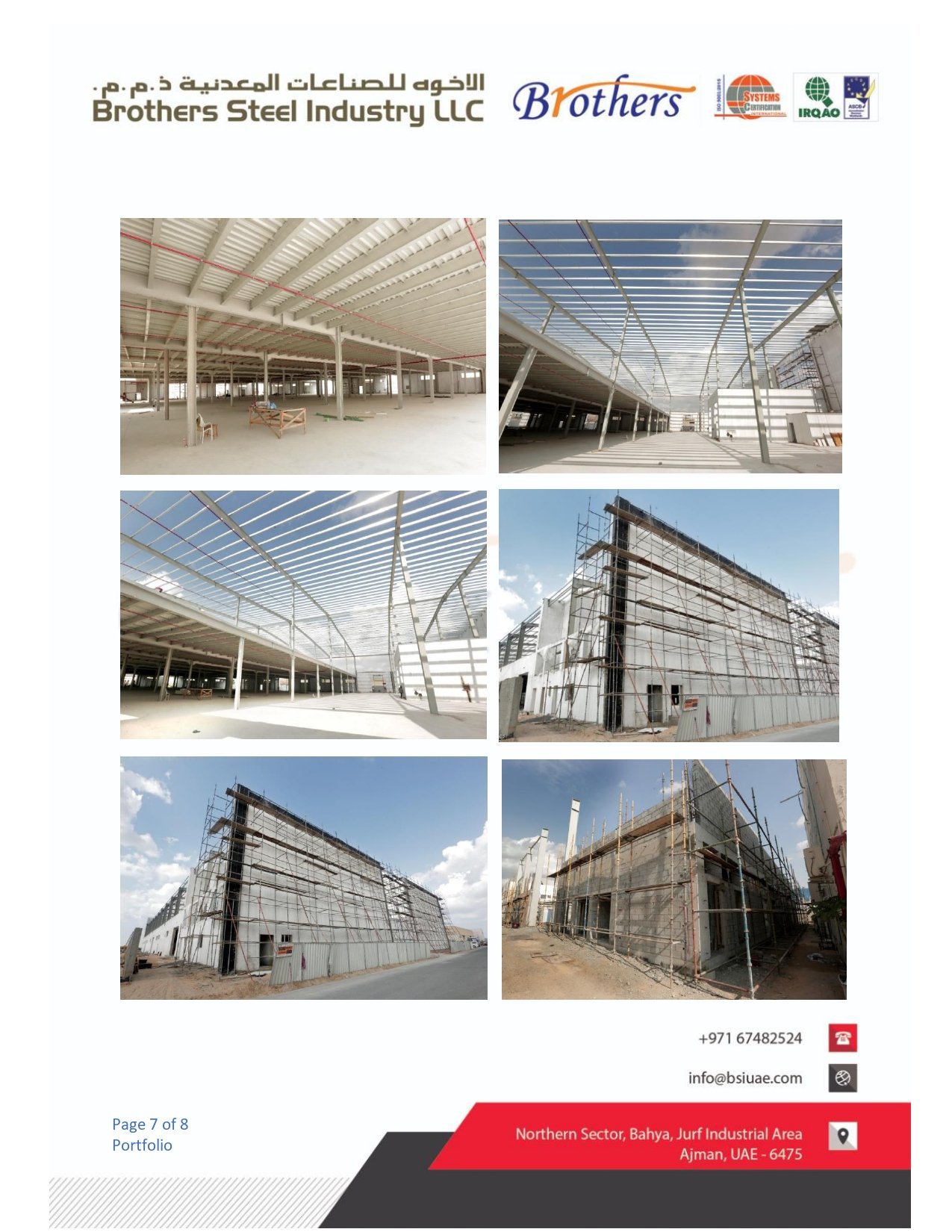

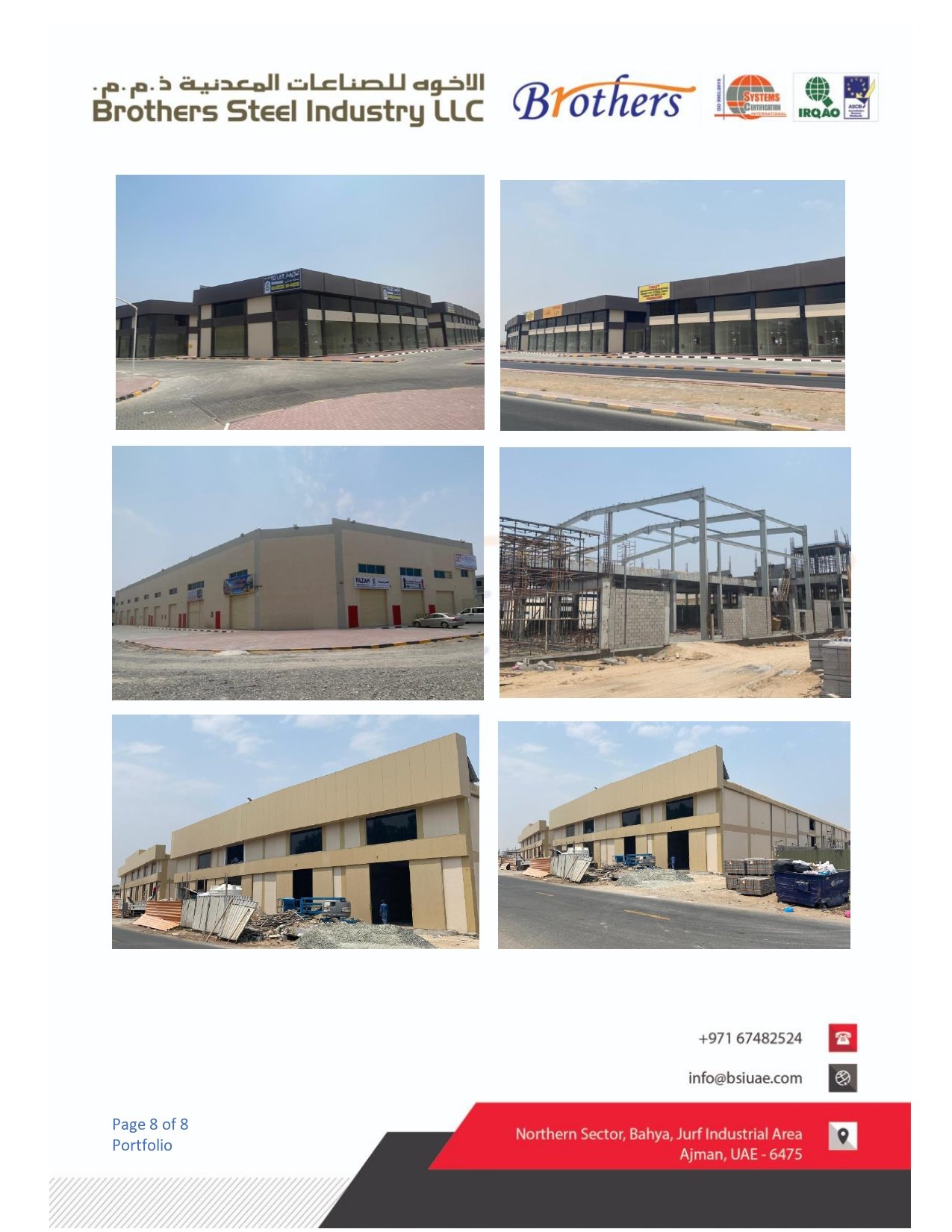

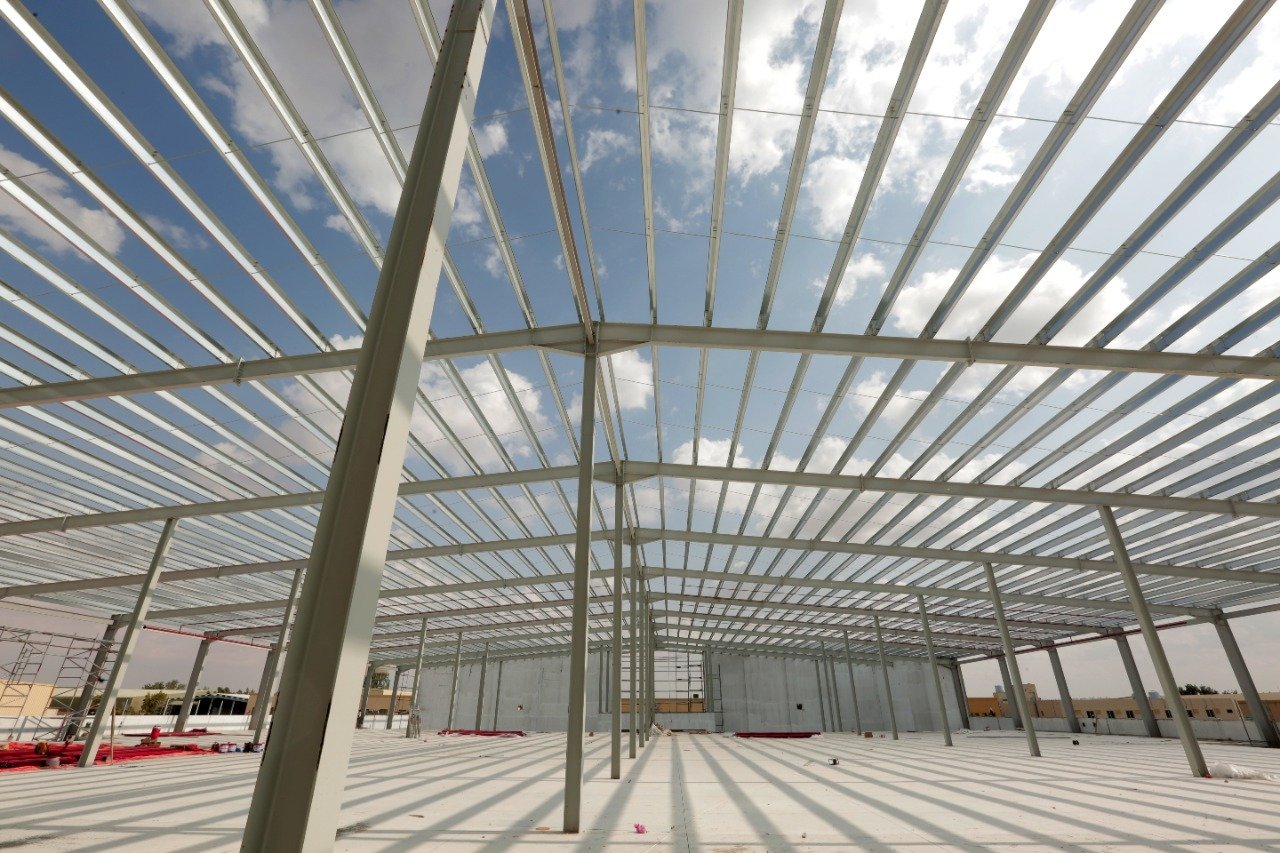

As the application of the structural steel buildings are vast and in order to meet the market requirements, we introduced the Structural Steel Fabrication division to our business. Our highly qualified Designers and Engineers are experts in design and detailing of structures, like: Warehouses, Factories, Showrooms, Shopping Malls, Go-downs, Workshops, Cold Stores, Labor Camps, Supermarkets, etc. The structural steel building fabrication works starts from the fixing of Anchor bolts up to the installation of mezzanine floor and roofing.

We undertake Structural Designs, Fabrication, and Erections of Structural Steel Buildings, Modification of Structural Steel sheds, and other Miscellaneous Metal Works etc. For the time being, our work is based on hot-rolled steel columns and beams. We are planning to start the PEB structural work in the near future. Our major scope of Fabrication works includes but not limited to the Design and Fabrication of Structural Steel Buildings, Warehouse Storage solutions, Mezzanine floors, Staircases, Handrails, Metal roofing, Wall panels, Structural steel canopies, Steel fences, Sliding Doors, Cat ladders, etc. We also undertake customer-specified fabrication works. We are one of the leading Structural Steel Fabrication industries in the region based at Ajman, UAE. Our production & fabrication factory is in the Jurf Industrial Area, Ajman, which accommodates the manufacturing spaces for the Steel Scaffolding, Aluminium Scaffolding and Cable Management system, along with Roofing & Wall Panel and Structural Steel Fabrication facilities. This large area helps us to cater the requirements of the large-scale fabrication projects. In this area, we have Laser Cutting Machines for cutting the plates for structural steel works. We also have machines for Blasting, Shearing, Bending, Notching, Welding, Drilling, etc. Our Protective Coating procedure for structural steel members include initial primer coating and two layers of synthetic enamel paint coatings. Most of the painting works are done using spray painting equipment. We take utmost care in handling the materials, for which we are using our Forklifts and boom-loaders. For loading the plates to the Laser cutting machine, we use our EOT (Electric overhead travelling crane). We would like to have a long-term business relationship with you, so that we can share our expertise and knowledge each other for both our mutual benefit and growth.